Cattle Feed (DDGS)

Give your livestock the nutrition they need to thrive with QTI's premium cow food.

Cattle Feed (DDGS)

DDGS is an excellent source of digestible protein and energy for cattle. It is highly palatable with a good source of readily available low-cost organic phosphorus and high in protein.The high energy level of DDGS is derived predominantly from fibre and fat and does not cause any risk of developing acidosis.

Distiller’s Dried Grains with Soluble (DDGS) is the dried residue remaining after the starch fraction of maize (Corn DDGS) is fermented with yeasts to produce ethanol. Following fermentation, the ethanol is removed by distillation and the remaining fermentation residues are dried.

Distiller’s Dried Grains with Soluble (DDGS) is the dried residue remaining after the starch fraction of maize (Corn DDGS) is fermented with yeasts to produce ethanol. Following fermentation, the ethanol is removed by distillation and the remaining fermentation residues are dried.

DDGS is an excellent source of digestible protein and energy for cattle. It is highly palatable with a good source of readily available low-cost organic phosphorus and high in protein. The high energy level of DDGS is derived predominantly from fibre and fat and does not cause any risk of developing acidosis.

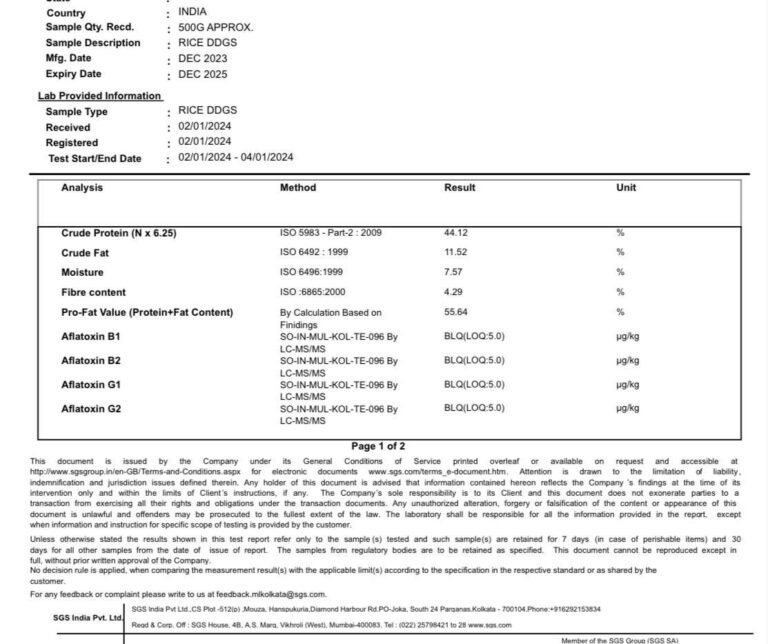

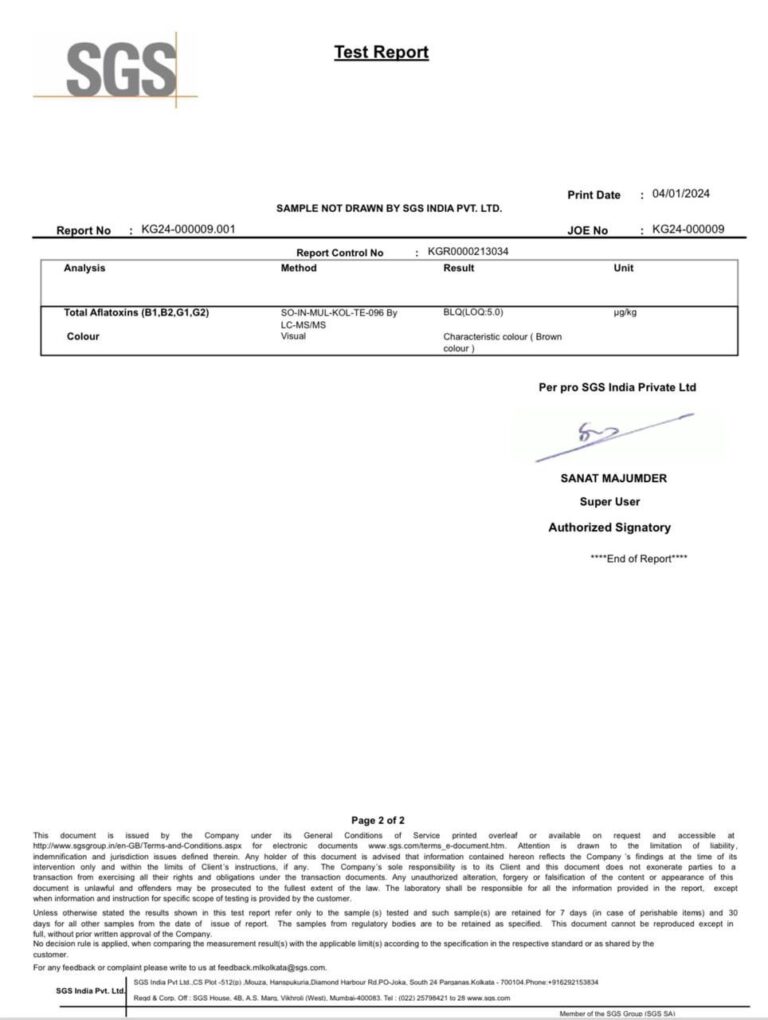

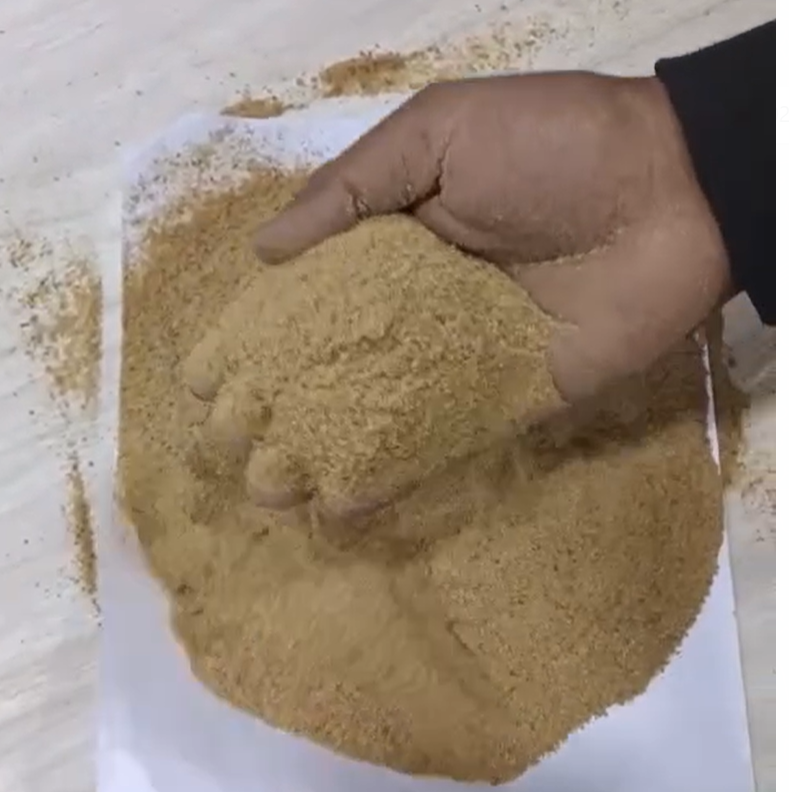

Rice DDGS is a by product of alcohol manufacturing process. Distillers extract the starch from grains to process into alcohol and the nutrients that are left over largely comprise of essential proteins, fat, vitamins that are in favour with poultry & cattle feed. Rice DDGS is good source of energy, protein, phosphorus.Distillers Dried Grains with Solubles (DDGS) has always been an alternative feed ingredient. It can be used as an alternate protein source as it is has a crude protein of around 40 – 45 % and gross energy of around 3800 – 4200 kcal/ kg can be used in commercial broiler chicken ration.

What is the manufacturing process of rice DDGS?

The DDGS production process

About manufacturing process of rice DDGS

Step 1: Rice Cleaning and Preparation

Step 2: Rice Grinding and Cooking

Step 3: Fermentation

Step 4: Distillation

Step 5: Drying

Step 6: Pelletizing and Packaging

Benefits of Rice DDGS

Rice DDGS is a valuable feed ingredient for livestock and aquaculture, as it provides several nutritional and economic benefits.